Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Weld Like a Pro, Wherever You Go!

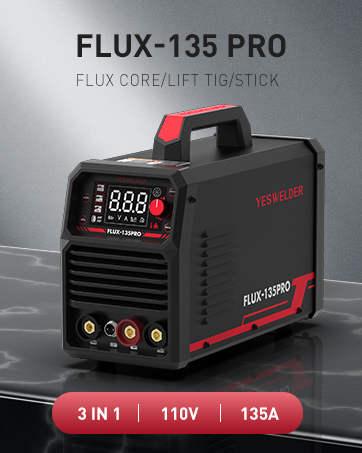

The YESWELDER FLUX-135PRO is a versatile 3-in-1 welding powerhouse delivering 135 Amps of output for mild steel up to 2/5” thick. Featuring a large LED digital display and synergic control, it auto-adjusts voltage with wire feed speed for precision welding. Lightweight and portable at just 11.4 lbs, it supports Flux Core MIG, Stick, and Lift TIG welding (torch sold separately), making it ideal for DIY enthusiasts and professionals seeking a compact, reliable, and budget-friendly welding machine.

| ASIN | B08CBBHFX5 |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #1,247 in Automotive ( See Top 100 in Automotive ) #1 in MIG Welding Equipment |

| Color | Black |

| Customer Reviews | 4.4 4.4 out of 5 stars (2,539) |

| Date First Available | July 3, 2020 |

| Handle Material | Metal |

| Item Package Quantity | 1 |

| Item Weight | 18.77 pounds |

| Item model number | FLUX-135 |

| Manufacturer | YESWELDER |

| Material | Metal |

| Part Number | FLUX-135 |

| Pattern | FLUX-135PRO |

| Product Dimensions | 17.4 x 13.74 x 7.56 inches |

| Shape | Rectangle |

| Size | Average |

| Special Features | Portable |

| Style | FLUX-135PRO |

| Usage | General Purpose |

J**R

Good value for DIY around the home projects

I am no professional welder, but I am an experienced engineer. Some decades ago I used a cheap stick welder on cars. Now with the 135 amp FCAW or "MIG" welder it is much easier on thin metal. The machine is much smaller and not as heavy, which I do also appreciate. I checked the output voltage and all looked fine. Then I tried it on a small piece of a metal stand for a fan - see picture after I painted it. It worked pretty good. Now it is stable to carry the fan. So the machine paid itself already half off because we do not need to buy a new fan. Here's a trick for thin metal sheets less than 1 mm: To only do sort of a spot weld and not burning holes into the thin metal the wire feed is way too fast. So to spot weld just leave the wire hang out of the nozzle long enough for a few spots and disengage the wire feeder by pulling off the wheel on top of the feeder. That way it won't feed when you press the gun button but it will weld when you hit the work piece with the wire hanging out of the gun. If you need more wire you can either engage the feed again or do it by hand until you get more wire out of the nozzle. Another option is to clamp a piece of wire with the stick welding clamp and use that instead of a welding stick. Just make sure it has the right polarity for MIG welding. Or you could even try to reverse polarity if that works better. The welding machine works fine and I do also like that it has a protection cover over the display and control knobs. Because sooner or later some sparks will hit the machine. What I usually do before I put it back to storage is to pull the wire back by hand into the machine. That way I have no loss of wire and I can disconnect the MIG gun and store it safely. The manual is pretty good, too. Not always the case with those cheap Eastern tools. What I did not test yet is the stick welding and the TIG welding. Stick welding should be fine though. It's much more simple than the FCAW welding and needs no feed. I am not sure if I will ever use TIG welding. I do only small DIY jobs around our home, nothing fancy or huge. A broken leg here and there or a frame part of a generator, swing, etc. Time will tell if the machine is reliable and should I run into problems I'll update my review. Update 9/29/2023: Now I welded a broken frame part of a canopy of a swing. It came apart after wind damage. First kinda "spot" welded then doing the "mig" flux core with the feed over it. Worked out just fine again. Although it was difficult to weld around the holes where the screw goes through. See pics before and after painting. It's also very thin metal. A little less than 1 mm. When using the MIG with about 40 amps and feed there was a lot of build up of metal, so I had to grind that off. Still stable and sturdy, so it has penetrated the frame enough. No issues with the welding machine so far. Did not check the higher amps over 90 yet, but I will probably not need it anyway. Those higher amps are for thicker material like 1/4 an inch or so. I have not many things here which are that thick and need to be welded. It would probably trip my 20 amp breaker anyways after some time. It says on the machine it needs 54 amps for that high of a setting. What I checked was the stick welding, just with the flux wire clamped in and two wires in parallel. That worked as well for the "spot" welding and clamping those 2 pieces of the frame together. In regards to suggest what welder to buy for just DIY small projects people: Forget the higher amps welders. They are more expensive, but not necessarily better for tiny jobs. Higher amps are for very thick metal. Good for pipeline welders or other professional jobs with HD jobs. But for tiny projects it's overkill. All you probably need is 100 amps max and for the most part with thin sheet metal 30-60 amps. Even then it needs some tricks to not burn holes into it. You can also try to use the mig wire to cut off a piece and hold it over small gaps and then weld it with the mig mode. That way you've got a thicker piece together to weld and the gap may be welded over easier. It's no rocket science, it's just hot metal melting and trying to get it back melted together. Whatever works, works! Quick Update 7/12/2024: Regarding the welds above they are still holding strong - no bending or weakness after almost a year. The swing frame outside and also the fan stand.

D**E

Impressive little guy

I have been using little cheap mig welders for about 20 years. I have welded more full exhaust then I can count. My old welder crapped out on me in the middle of an exhaust. So I needed a welder fast. This arrived over night. So far I love this little welder. Set it to flux, and used the setting it was on when I first turned it on. (420). Seemed like a good number to start with. I am making very nice welds with this. Way better then with my old one. I learned that with no gas, you shouldn't try to pull a long bead. Just make a spot weld the size of your fingernail. (pinky nail). Stop (pause). When the red glow dies, place another spot weld overlapping the last one. Stop (pause) wait for red glow to die, and repeat until you have completed the whole thing. This will ensure you have nice looking welds, and you don't burn through the metal. Make sure the surface is clean. After 4-5 spot welds, stop and use a wire brush to remove residue, then keep going. Rinse and repeat. If you don't want spatter on the surface around the weld, then cover the area with a wet cloth. Wrap it in wet leather. Something like that, you get the idea. Initially the wire was a pain to get started. Be patient. Remove the tip at the end of the feed first. Once it was all set up, it works nicely. I really love how light it is. Very portable. And easy to store. I am impressed with this $100 welder. Every man should own one and teach himself to weld. Save a lot of money, and it's fun too. If you complete just one task that you normally would have paid someone to do, then it has already paid for it self.

C**N

Ease of use brilliant functionality

So, very pleased with this product. I found this on sale for $99 on Amazon. It came complete with a spool of flux core wire. Ready to weld out of the box? You can't buy much for a 100 bucks when it comes to welding or so. I thought I was thoroughly impressed by this unit. I am fairly new to welding. However, Wanted to be able to teach myself via YouTube university. I am pleased to say this unit functions. Well, and comes complete with more than enough information to make you successful with this one machine. You are able to flux, core weld. Stick weld and even lift tig. Weld, however, the lift tig Torch is bought south Separately cannot beat it for this price point here, below are some samples of what this welder can do not a professional by any means

3**Y

Great priced beginner welder for small projects

I was a welder for a while and had access to all the best tools and welders. I needed to build a small side table out of tube steel and started searching for a welder under $200 that could do multiple types and handle up to a 3/16" thick steel. The listing for this is a little misleading, it says it can handle 2/5" thick steel which is .4", just under 1/2". The manufacturer information says it can only do 3/32" max. You might get a little more if you chamfer the edges. So make sure you don't need something more substantial. I went with flux MIG because I researched how much it would cost to rent a tank and buy gas and it was a few hundred dollars. I don't plan on using this a ton so it just didn't make sense to get gas, which is by far the better way to go over flux. I love that it has the stick and TIG option, not sure how TIG will work out without gas though. I have only done MIG so far but I'll give stick a shot and see how that goes. The welder is lightweight and the gun and hose are appropriate quality for this level, but it would be worth upgrading them in my opinion after using a more expensive set up before. The hose is cheap material and at one point it pressed up against a recent welded joint and melted the outer jacket. Luckily I noticed before it damaged any of the internals. I can appreciate that the wire feed speed and current are combined into one knob for beginners but - much rather have the control over the two settings individually. It took some tinkering and never really got it consistently dialed in for higher current. The welds were hit or miss but some of that was me having not welded in several years. It would sputter on welds on interior corners, I'm guessing because the nozzle shroud was preventing it from getting to close to the metal. Most of the interior corner welds would come out cold and had to be redone. Butt welds and outside corners were pretty good. It does a pretty good job of a small puddle weld or tack though. It works pretty well on tube, not sure how it would do on thin plate steel, especially with out chamfering any butt joints. The flux MIG makes a huge mess of the weld and anything around the work area. I had some hand tools nearby and they are all covered in tiny black specs so make sure to move anything away that you don't want to get dirty or burns. It's nice that it works on 120V and doesn't trip my breaker at all. Overall I am pretty happy with it, it came down to this or the Toolio.

J**J

Good welder for hobbyist or homeowner

I’m not a professional welder or anything but for $109 I don’t not think this is a bad deal at all. Although there are tons of mixed reviews on the 135 and a lot of it is probably from poor quality control from the pictures and reviews I read, I think it’s a good machine for a hobbyist or homeowners who has small projects occasionally. And I may have just got lucky and received a “good one” so I still advise do your own research into the welder before purchase and verify it is designed for what you need. Compared to my harbor freight welder (Chicago electric 125) this thing knocks it out of the park which I truly believe is because it’s a DC machine that you can swap your leads around for proper polarity for different styles of welding. I have not tried tig welding with it yet because I have not purchased a tig torch after seeing how it handles flux core and stick I think it will do well. This welder will not take the place of a good Lincoln or miller or other big name or high quality welders but definitely has its place and does the job pretty well. It’s not the best but it’s definitely not the worst either way it falls in the middle for me. All in all I give it a 7/10 because again for $109 and it welds smooth and hasn’t gave me any issues and for what it is designed to do it does it well.

C**M

Great 110v welder

Awesome welder for a little over $130 Great wire speed dial and heat level. Very easy to adjust from tig, mig, and stick welding. It’s a steal at that price.

R**Y

10/10 Highly Recommended

I’m new to welding, and this model has been an absolute joy to learn with. The YESWELDER FLUX-135PRO has given me peace of mind right from the start, knowing I have a reliable tool and solid support behind it. A standout moment for me was when I accidentally broke a piece of the flux core setup. The YESWELDER team responded incredibly fast and helped me get a replacement quickly. Their quick, friendly assistance turned a potential setback into a seamless experience. So far, this machine has been awesome for beginners like me, and I’m excited for the projects I’ll tackle in the future. If you’re considering a welding unit that’s reliable, well-supported, and beginner-friendly, I highly recommend the YESWELDER FLUX-135PRO.

D**N

Good welders, Fluxcore 135 and Mig250 Pro

I own the Fluxcore 135, and the Mig 250 Pro welders. They're both good welders, although cheap (build and price). The welding charts for these welders are metric. These are hobby/DIY welders and both come with a 1 year warranty. Fuxcore 135 Works well for a 110V welder. This is a DC only welder (DCEP + DCEN). It's capable of Fluxcore and Stick welding only. The amperage displayed on the screen for stick seems off (less than it actually is by im guessing 10-15 amps). You can weld up to ⅛ thick steel with this welder. The wire spool holder and wire tensioner are cheap and poorly made but function. The stinger, electrode holder and ground clamp are cheap but work good enough. I've welded .030 and .035 fluxcore wire for mild steel with it and it's easy to set wire speed, wire size and voltage trim (not actual voltage). You cannot set volts with with this machine in Fluxcore mode as it's a synergic only machine. Amperage and volts adjusts automatically with wire feed speed, the higher the wire feed speed the higher the amps and volts. It welds good, holds a consistent arc and wire feed speed is consistent and steady. When welding Fluxcore you "pull" away from the weld pool when traveling. I have it tied into a 110V 20 amp outlet and never tripped the breaker. I'm impressed with this welder for the price of the unit. Mig 250 Pro This is a much nicer welder compared to the Fluxcore 135, as it is a 220V (only 😢) welder and is capable of higher amps and types of welding. It has 10-25 European cable connectors. You can weld up to ½ with this welder. It does Stick, Mig, Pulsed Mig, Fluxcore (I'm guessing Dual Shield Fluxcore as well) and lift Tig, Tig torch not included. DC only on all types of welding, so no aluminum welding on Tig. It can Mig weld SS with 98/2 gas and ER308L wire. Aluminum with 100% argon gas and ER4043 wire, with (or without) a spool gun, spool gun not included and of course mild steel with ER70S-6 wire. It comes with a graphene stinger liner you need to change to if you want to feed wire thru the stinger without a spool gun for aluminum (but normally this isn't recommended). I've used this welder for Stick and Mig (with C25 gas) welding so far. It accepts 2lb and 10lb wire spools. It has an inching button to fastely feed wire during the initial setup. With a 10lb spool loading wire is tedious and tight spaced. To adjust spool tension rotate the iron nut on the spool holder clockwise for tighter/counter clockwise for looser. For wire tension with Fluxcore wire don't over tighten the tensioner or you'll crush your wire. Mig (with gas) with solid wire can have a higher tension. As with the Fluxcore 135 this unit has a cheap wire spool holder, electrode holder and ground clamp. The stinger is nice but is only rated at 150 amps. If you weld in manual Mig mode with maxed out voltage and wire speed you'll fry the stinger. The tensioner is nice and comes with different rollers for Flux core steel and SS (W knurled type .035 roller), Mig steel and SS (V type .023, .030 and .035 rollers) and Mig aluminum (U type .035 .045 roller). I have it tied into a 220V 50amp outlet and haven't had any problems with the breaker tripping. I feel like the amperage may be less than the screen indicates, by maybe 10-15 amps less than shown. I've ran 7018, 6013 and 6010 electrodes on Stick, all 3/32nd's. The unit seems to not work with 6010 rods as they just don't weld properly (This is common on power inverter type welders). The 6013 and 7018 electrodes weld great! I'm very pleased with this welder in stick mode both DCEN and DCEP. It has multiple settings you can adjust along with the amperage for stick welding including hot start, arc force (DIG), anti-stick and VRD (voltage reduction in high moisture/humidity environments for safety). For Mig it has wire feed speed, burn back time, inductance, hot start, 2T/4T, voltage trim (-5/+5 with each number representing 0.3 volts in synergic Mig) and volts (in manual Mig). For Mig welding I've used .030 solid wire ER70S-6 (10lb spool) with C25 as my gas at 20CFH at the regulator and it welds great. I haven't ever hit duty cycle but it's 60% at 250 amps. I've used it in Synergic MiG mode only. It has manual mig where you can set the volts. This machine should be capable of spray transfer Mig with .035 wire in manual Mig with 90/10 gas and an upgraded 250 amp stinger. I'm not sure what gas option you would pick on screen though. In Synergic mode it's dialed in on its own, you just set wire feed speed and the type of gas your using. I replaced the ground clamp with a 300 amp Lincoln clamp, the electrode holder with a 250 amp Lincoln and the stinger with a Euro connection 250 amp Tweco #2 knockoff. The welds I lay down with this unit on Mig are fantastic! Once my bottle is empty I'll get 100% Argon and try out Tig. This welder is not foot pedal compatible for Tig. Both welders are a great bang for your buck! I'll run the machine on max amps for stick and max volts and wire feed speed for MiG and use an Amp clamp to see if it really puts out as much power as it says then I'll update my review.

Trustpilot

2 days ago

1 month ago