Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔧 Cut like a pro, carry with confidence.

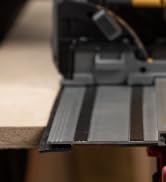

The POWERTEC 71550 Track Saw Guide Rail Kit includes two 55-inch extruded aluminum guide rails, connectors for extended cuts over 9 feet, and a durable padded carrying bag. Engineered for high precision and compatibility with Makita and Festool saws, this corrosion-resistant kit delivers professional-grade straight cuts while protecting your tools during transport.

| ASIN | B08BR64FWK |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #37,968 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #22 in Circular Saw Accessories |

| Customer Reviews | 4.0 4.0 out of 5 stars (632) |

| Date First Available | June 24, 2020 |

| Included Components | (1) Track Saw Rail Bag, (2) 55" Guide Rails, (2) connectors |

| Item Package Quantity | 1 |

| Item Weight | 14.97 pounds |

| Item model number | 71550 |

| Manufacturer | POWERTEC |

| Material | Aluminum |

| Part Number | 71550 |

| Power Source | electric |

| Product Dimensions | 58 x 9 x 5.75 inches |

| Size | 55"x2 Guide Rail w/ Bag (for Makita or Festool) |

| Style | 55"x2 Track Saw Guide Rail w/ Bag (for Makita or Festool) |

B**R

Exactly like the Makita track

I was sceptical by the price point, but these tracks are almost identical to the Makita tracks. I had two short Makita tracks but needed the long size for 8' rips on job sites. Joining these two works perfectly, plus you get the case for about 2/3 the cost of one long Makita track. The only thing I've noticed is that the adhesive on the rubber rip edge is not quite as good. But that can easily be replaced when needed.

D**.

Perfect!

Love this track with my Makita track saw. Works great, no alignment issues, track is true. Fits together nicely, and really is simple to use. Wish I had this years ago!

J**E

Works great

Works well with festool. Pads on bottom Coming off on one track which is annoying since I’m very particular about caring for the tracks. So it’s a cheaper product but it works fine.

M**Z

Please Don’t Buy This! Powertec, Do Better!

I’m one of those “don’t really review unless it’s really terrible” type of people. When I shop on Amazon I take negative reviews with a grain of salt. Sometimes I think it’s user error or a “one-off” faulty product. In my case I know it’s not user error, but perhaps it’s a “one-off” but it’s a very expensive one-off for me. I have the cordless DeWalt track saw and I needed a track long enough to rip 8’ plywood sheets. I wanted the genuine track. I would have paid the extra money for the track…but I couldn’t find it in stock anywhere. Every site I searched said it would take 3-4 weeks to ship. I needed it right away. I use to have the Wen track saw and had the Powertec track and it worked great. I decided to buy the Powertec track for my DeWalt saw. I read a lot of bad reviews about the splinter guard not staying on but didn’t worry about it. Sure enough, when I got the saw I had the same problem. Splinter guard would not stick. I peeled it all off and used fastback tape to reapply and it still peeled off. I spent $30 to buy Makita splintergaurd tape and that worked perfectly. On to the REAL problem: my first cut was an 8’ rip 12” wide. After trimming the splinter guard I moved on to working with the track. As I made my cut I realized the 12” wide strip was a 1/16” more narrow in the middle!!! I thought. It was a flaw in the track design. There is only one rail holding the two track pieces steady. I thought maybe they flexed as I was cutting. I used JB Weld to fuse the two tracks together in hopes the two pieces wouldn’t flex during my next cuts. Used a level to check the splinter guard and saw that it was perfect! Made two more rips on a sheet of plywood and noticed I was still off a 1/16” of an inch halfway through the 8’ rip. I realized the rail that the saw rides along was off!! 😡 I can’t fix the track. Plywood is so expensive right now (note:I was cutting 3/4” cherry plywood) and I spent extra money on new splinter guard. I could contact Powertec and ask that they send me a new track, but I doubt they will reimburse me for the $100 sheet of ruined plywood, the $30 in splinter guard, $12 in fastback tape and $8 in JB weld. I’m just going to use my mitersaw to chop this piece of junk in half again (as it came) and send it back and wait for the 102” Dewalt track. Hopefully I’ll have better luck.

A**R

Good Value but with a few manufacturing issues

This Powertec track has all of the same features as the more expensive Makita version. It holds the XPS01 track saw and slides with no issues and supports the anti-tip lock needed for bevel cuts. The rails arrived true and connected together with no issues. There is some minor slop where the saw attaches to the rails. Being new to track saws, I can't say if this is normal or poor tolerance. I'm aware of it and will be sure to push the saw against the track when cutting. The Powertec kit (2x55" rails, 1 carry bag, 1 connector spline set) was delivered with two manufacturing issues: 1) the bottom glide strip on one rail was loose and had lifted so the adhesive side was on top of the saw track; and 2) the case's Velcro strap ends were sewn together so they couldn't surround the track in the carrying bag. I was able to reposition the lifted glide strip and it now seems secure. Getting all the deposited adhesive out of the track was a pain (Thank You Goo Gone, but minus one star). Some careful pulling separated the Velcro strips from where they were incorrectly over-sewn. Both of these problems should have been caught with a better quality inspection. One difference from the Makita OEM version is the design of the guide connector splines. The Makita uses two thinner splines and the set screws push them apart to secure the track. The Powertec uses a single spline and the set screws deform the aluminum of the track itself. The Powertec spline design requires inserting the two splines so that the set screws on one are facing up and the other facing down. You have to tighten the four up set screws and then carefully flip the rails over to tighten the other four. More cumbersome than I imagined. For my homeowner use the Powertec splines are adequate... even though not ideal.

D**.

just ok

These rails are ok. They need 2 points of connection to stay square to each other. The rubber strips that the saw glides on are constantly letting go and have to be glued down. There are better options.

A**R

Much better than the Milwaukee track rails

I use Festool and Milwaukee. Although Festool has a slightly better product in general, I really enjoy the convenience of the Milwaukee batteries. Pros compared to Milwaukee: - the biggest pro by far is the rubber splitter, it’s way better!! It’s thicker and more rigid and feels like it’s apart of the track rather than a piece of crappy door seal. I’ve replaced the rubber splitter twice on Milwaukee rail. It peals off when the slightest amount of dust gets in there or warm weather releases the tape. - slides a lot easier due to the ribs in the plastic sliders. - grips better to cutting service. Cons so far: - very slightly out of square on one of the edges. Meaning you just have to double check when connecting them end to end to get a perfectly straight line.

S**7

Work, but nowhere near as good as the Dewalt branded units

Works for Dewalt saws as described but they're not at the quality level as the Dewalt tracks. If I could have found the Dewalt branded tracks, I would have bought those instead and would advise the same. 1 big drawback is the adhesive holding the strips in place is not good at all. Within hours of the first use, they were peeling up/off and I have to reset them constantly. This is especially annoying when I have the tracks mated together because they peel at the ends and as you move the saw across the lip, the saw's leading edge lifts the peeling guide and then peels it up like an apple skin. You have to stop the cut, remove the saw, reset the guide strip.. Etc. Regarding using two tracks together, the Dewalt OEM version has chamfer in the extrusion and on the adapter bar such that when you tighten the set screws, the 2 angled surfaces attempt to center the adapter in the extrusion, thereby attempting to center /align the tracks to each other. These tracks have no such features. The surfaces are all just rectangular, which means there has to be some side to side play between the adapter bar and the extrusion.. Thus, if you don't specifically try to align the extrusions together, then the tracks will be misaligned when you tighten the set screws and your saw will jam as you try to traverse the seam.

Trustpilot

3 weeks ago

1 month ago